Miller Deltaweld 500 MIGRunner w/Single Intellx Pro Feeder (230/460V) (951808)

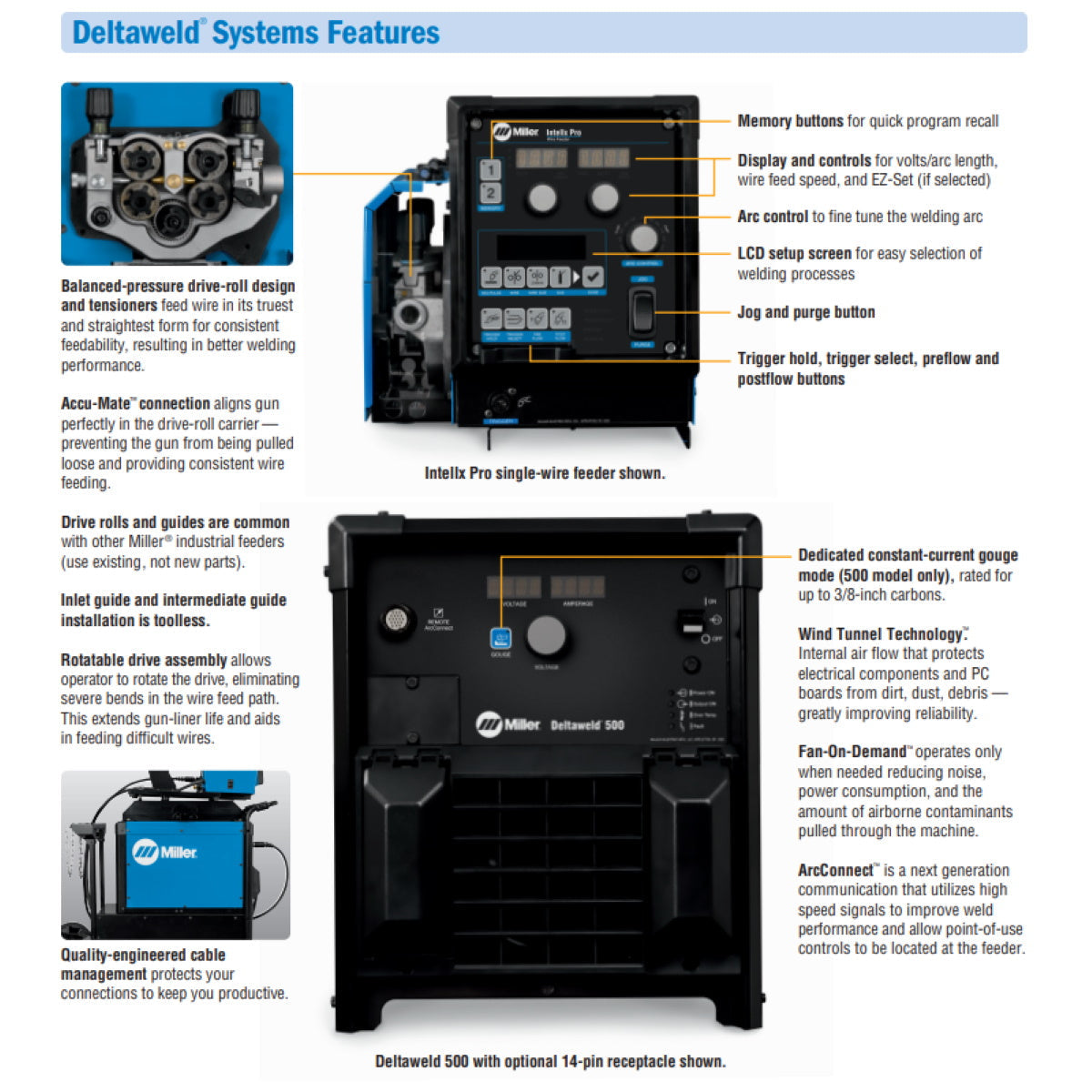

The Miller Deltaweld 500 power source comes with ArcConnect, Accu-Pulse technology, and digital meters. Accu-pulse process allows for precise control of the pulse arc. This technology also provides optimum molten puddle control and has power to increase wire feed speeds and deposition 20 to 25 percent in many applications. The Deltaweld comes with several of Miller's standard features such as Wind Tunnel Technology and Fan-On-Demand, yet features their newest generation of technology called ArcConnect. ArcConnect utilizes high speed signals to improve weld performance and allow point-of-use controls to be located at the feeder.

The Deltaweld 500 comes standard with digital meters and auxiliary power with an optional 14-pin receptacle. These units also feature a dedicated CC gouge mode rated up to 3/8" carbons.

This particular Deltaweld 500 does NOT come with a 14-pin receptacle, rather utilizes the ArcConnect cables.

The Intellx feeders come with digital meters, remote voltage, arc control, and jog/purge controls. The drive system comes with a balanced-pressure drive roll design that feeds wire in its truest and straightest form for consistent performance. The accu-mate connection aligns gun perfectly in the drive-roll carrier, preventing the gun from being pulled loose and providing consistent wire feeding. This particular package includes the Intellx Pro feeder, which allows more capabilities like stainless, flux-cored, metal-cored, different wire types, and different gas types.

Deltaweld Features

• Accu-Pulse Technology

• EZ-Set Parameters

• ArcConnect Technology

• Fan-On-Demand

• Wind Tunnel Technology

Deltaweld Quick Specs

• Output Range: 30-650A | 10-44V

• Duty Cycle: 60% @ 575A | 100% @ 500A

• Input Power: 230/460 | 3-Phase Only

• Weight: 405 lbs

Intellx Features

• EZ-Set MIG

• EZ-Set Accu-Pulse

• Memory Recall Buttons

• Digital Display

• Arc Control for fine tuning

• Jog and Purge Button

• Balanced-pressure drive roll design and tensioners

• Rotatable drive assembly

Intellx Quick Specs

• Duty Cycle: 60% @ 600A

• Wire Feed Speed: 50-780 IPM

• Wire Diameter: .023-5/64

• Max Spool Size: 18 inches | 60 lbs

• Weight: 44.8 lbs

• Dimensions: 16.25"H x 12.38"W x 27.88"L

Includes

• Deltaweld 500 Power Source (907785)

• Single-Wire Intellx Pro Feeder w/15 foot Bernard Gun

• Running Gear w/Dual Cylinder Rack

• Flowmeter Regulator w/Gas Hose

• 4/0 Weld Cable with Lugs

• Work Cable with 600 A C-clamp

• 9 Foot ArcConnect Cable

• .035/.045 V-Groove Drive Rolls

• Spare Bernard Centerfire Contact Tips

The Deltaweld 500 comes standard with digital meters and auxiliary power with an optional 14-pin receptacle. These units also feature a dedicated CC gouge mode rated up to 3/8" carbons.

This particular Deltaweld 500 does NOT come with a 14-pin receptacle, rather utilizes the ArcConnect cables.

The Intellx feeders come with digital meters, remote voltage, arc control, and jog/purge controls. The drive system comes with a balanced-pressure drive roll design that feeds wire in its truest and straightest form for consistent performance. The accu-mate connection aligns gun perfectly in the drive-roll carrier, preventing the gun from being pulled loose and providing consistent wire feeding. This particular package includes the Intellx Pro feeder, which allows more capabilities like stainless, flux-cored, metal-cored, different wire types, and different gas types.

Deltaweld Features

• Accu-Pulse Technology

• EZ-Set Parameters

• ArcConnect Technology

• Fan-On-Demand

• Wind Tunnel Technology

Deltaweld Quick Specs

• Output Range: 30-650A | 10-44V

• Duty Cycle: 60% @ 575A | 100% @ 500A

• Input Power: 230/460 | 3-Phase Only

• Weight: 405 lbs

Intellx Features

• EZ-Set MIG

• EZ-Set Accu-Pulse

• Memory Recall Buttons

• Digital Display

• Arc Control for fine tuning

• Jog and Purge Button

• Balanced-pressure drive roll design and tensioners

• Rotatable drive assembly

Intellx Quick Specs

• Duty Cycle: 60% @ 600A

• Wire Feed Speed: 50-780 IPM

• Wire Diameter: .023-5/64

• Max Spool Size: 18 inches | 60 lbs

• Weight: 44.8 lbs

• Dimensions: 16.25"H x 12.38"W x 27.88"L

Includes

• Deltaweld 500 Power Source (907785)

• Single-Wire Intellx Pro Feeder w/15 foot Bernard Gun

• Running Gear w/Dual Cylinder Rack

• Flowmeter Regulator w/Gas Hose

• 4/0 Weld Cable with Lugs

• Work Cable with 600 A C-clamp

• 9 Foot ArcConnect Cable

• .035/.045 V-Groove Drive Rolls

• Spare Bernard Centerfire Contact Tips

| MPN: | MIL951000149 |

|---|---|

| UPC: | 715959717960 |

Brands you trust at prices you can afford!

Over the past decade, we've become the country's most trusted one-stop online welding shop. We've done it with the guaranteed lowest prices, the best customer service in the industry, and a commitment to providing the best online shopping experience for all welders.

------------------------------

From The Blog

Stick

ESAB HandyArc 1/8 – The Smallest Welder You’ve Ever Seen

ESAB’s newest stick welder, the HandyArc 1/8, proves that size doesn’t matter – at least when used correctly. While this machine won’t be perfect for every situation, it’s one of the most portable ...

Helmets

The Ultimate Guide to Lincoln Welding Helmets

It’s a good feeling: Walking up to a job site with your Lincoln Viking helmet while the other welders eyeball you like “Oh dang, wish I had a hood like that!” With their reliability, comfort and pr...

MIG

How to Get the Best Price on the Millermatic 252

As one of Miller’s most beloved MIG machines, the Millermatic 252 is a beast with the highest output in its class. This workhorse of a welder should be considered an investment in your capabilities...

Download Product Spec Sheet

Download Product Spec Sheet